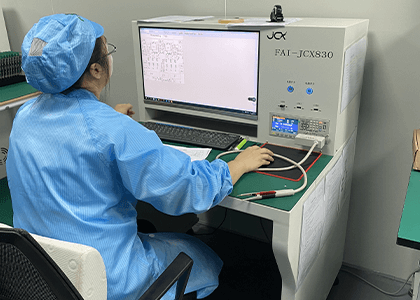

Each circuit board passes through a complete testing mechanism. The testing processes include in-circuit testing and 100% functional testing. Further, we look at calibration/ adjustment, parameter setting, optoelectronic assembly controls.

- SPI (Solder Paste Inspection)

- AOI (Automated Optical Inspection)

- X-ray (Automated X-ray Inspection)

- Flying Probe

- HP TestJet Technology

- ICT (In-Circuit Test)

- Life Cycle Testing

- Screening Techniques

- ESS (Environmental Stress Screening)

- HALT (Highly Accelerated Life Test)

- HASS (Highly Accelerated Stress Screening)

- Test Development

- Visual Inspection