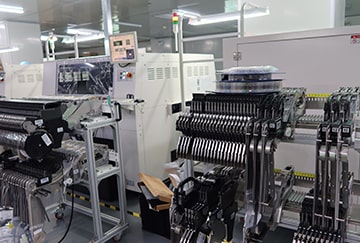

(Panasonic NPM-D3)

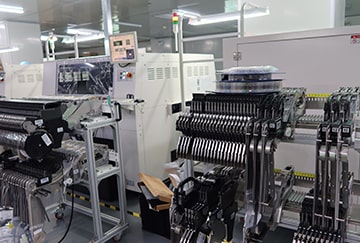

(Panasonic NPM-TT)

(Germany Ersa)

PCBAMake offers one-stop PCB and PCBA manufacturing services, from PCB production to final product assembly. We provide efficient and flexible solutions to turn your ideas into reality.

| Assembly Type | Typical Volume |

|---|---|

| PCB Prototype | 1–20 pcs |

| Early Production | 20–50 pcs |

| NPI | 50–100 pcs |

| Small Batch | 100–1000 pcs |

| Medium Volume | 1000–10000 pcs |

| High Volume | 10000+ pcs |

PCB Manufacturing Quality Certification

14001:2015

ISO9001:2015

ISO13485:2016

UL

ROHS

IPC

SGS

We support small-batch customized production of single-sided, double-sided, multi-layer, high-frequency, flexible, and rigid-flex boards to meet diverse design requirements.

With access to global supply chain resources, we ensure the quality and reliability of components. Our dedicated warehouse in HK helps save on import taxes and shipping costs, reducing overall expenses.

With 3 advanced SMT assembly lines, 2 manual insertion lines, and professional testing equipment, we ensure the performance and quality of every product.

Our quality control includes AOI, X-ray, FPT, and visual inspection. Every order undergoes strict quality checks and inspections before shipment.

From product assembly to custom enclosures, packaging, and logistics, we provide one-stop delivery services to bring your products to global markets seamlessly.

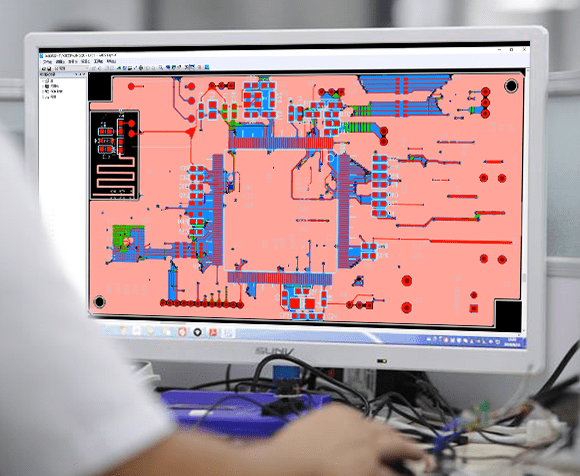

We offer professional free DFM checks during small-batch PCB assembly, thoroughly reviewing your design files (Gerber, BOM, assembly drawings, schematics). Our engineering team ensures manufacturability and assembly readiness, safeguarding your production.

Ordering small-batch PCB assemblies saves costs and allows errors to be identified and corrected at the right time. In contrast, errors in large-volume production can lead to significant losses and wasted time. Therefore, small-batch PCB assemblies are highly essential.

How to get an official quote before placing your order: For a small-batch PCB assembly quote, email your BOM and Gerber files to poe@pcbamake.com.

* Only zip or rar files accepted. Max 18MB.