| 1 |

Lead Time |

Our assembly time ranges from 24 Hours to a few weeks. Please choose appropriate time option to fit your schedule and budget.

Due to the complexity of how to determine the turn time of PCBA services, our policy is that turn-time begins immediately after all the parts are ready and all the PCB files (Gerber files/other PCB files, etc.,) , Pick & Place PNP file, or XY Data or files in other formats), BOM, and all other necessary data or documents/images/photos are complete for our assembly work. |

| 2 |

Parts Source |

| Consigned/kitted |

We prefer we supply all the parts for the PCBA services for our customers. In this case, please send us all the components with BOM file and detailed packing list indicating item number, customer or manufacturer’s part number and quantity in kit. |

| Turn-key |

With our wide and powerful network of parts sourcing, we offer Turn-key PCBA service. We do not mark up on the parts cost. Considering the big price gap between different suppliers, we only source from reliable suppliers who may have no price advantages. We will always ask for your approval before making any decisions. |

| Partial Turn-key/Combo |

This is our regular practice which you offer the main devices and components, while we source the rest for you. Just like the Turn-key service, we will ask for your approval on every details of the parts concerning price, quality and availability. |

|

| 3 |

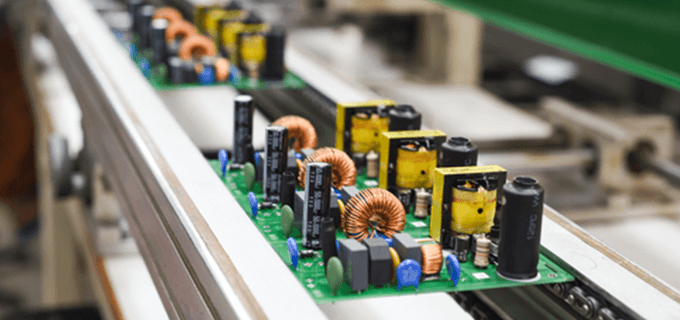

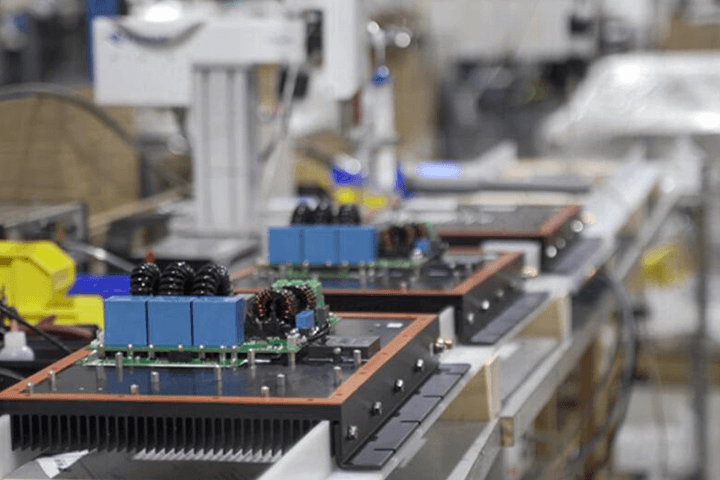

Assembly Options |

We offer Surface Mount (SMT), Through-Hole (THT) and a conbination of both. We also offer single or double-sided placement. We make the SMT and DIP jig for your projects, this jig is one time charge. |

| 4 |

Types of Solder |

We offer both leaded and lead-free (RoHS Compliant) assembly services for our customers. Please choose one to best fit your PCB and the parts on the PCB. |

| 5 |

Stencils |

We use laser cut stainless steel stencils to ensure high reliability for fine pitch and BGA components. Red ink coating is available upon request. |

| 6 |

Minimum Order |

Our minimum is as low as 1pcs. We do not want you to pay for what you do not need indeed to save you money. And for shipping less than 2kgs, we do it for free. |

| 7 |

Component Size |

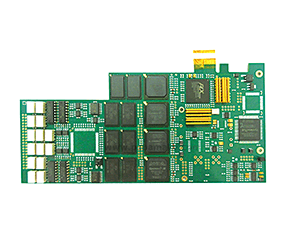

Passive Component: we can accept components as small as 01005, 0201,0402.

BGA: We have the ability to handle BGA of 0.3mm pitch for rigid PCBs and 0.4mm for flex boards with X-ray testing. (The details can be confirmed according to the board design.)

Fine Pitch Parts: we can assemble 0.25mm fine pitch parts. |

| 8 |

Component Package |

We accept parts in Reels, Cut Tape, Tube & Tray, Loose Parts and Bulk. |

| 9 |

Board Dimension |

Min Board Size: 50mm x 100mm (Boards smaller than this size need to be panelized)

Max Board Size: 250mm x 500mm |

| 10 |

Board Shape |

We can assemble boards in Rectangular, Circular and any Odd Shapes. (For shapes other than rectangle, you need to panelize the boards in an array, and add break-away rails at the two longer paralleled edges of the panelized boards to ensure that the boards can be assembled by the machine.) |

| 11 |

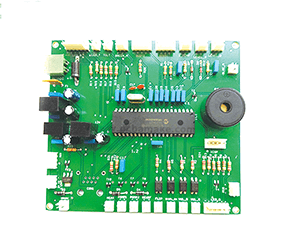

Board Type |

Rigid boards ,flex and rigid-flex boards, please contact poe@pcbamake.com if your boards are of other materials. |

| 12 |

Repair & Rework |

Repair and rework can be difficult, but we do. Our BGA reballing service with which we can safely remove the misplaced BGA, reball it and put it back on the PCB correctly. It is cost-effective. And we repaird the bad boards sometimes without any cost, please feel free to contact us at poe@pcbamake.com |