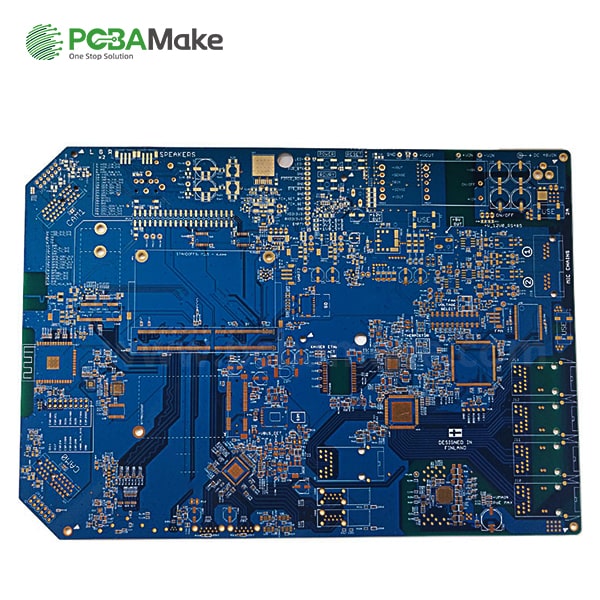

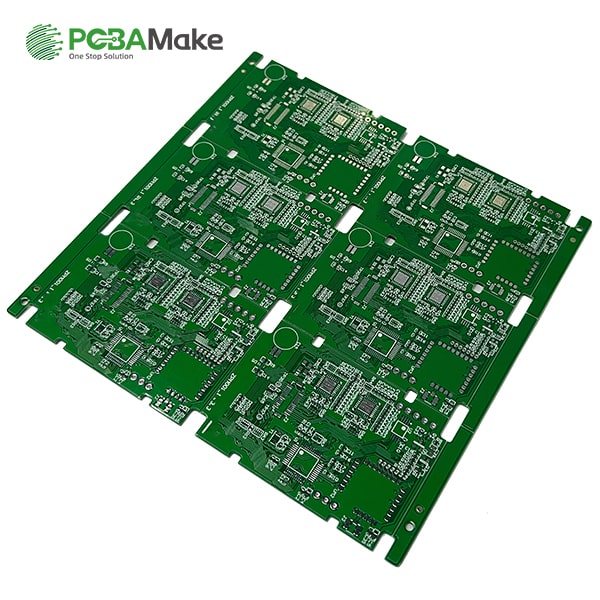

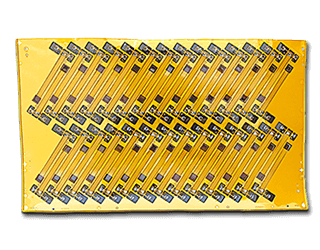

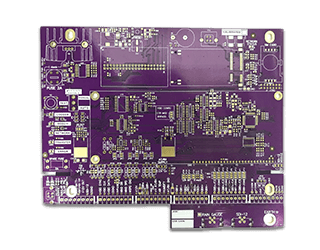

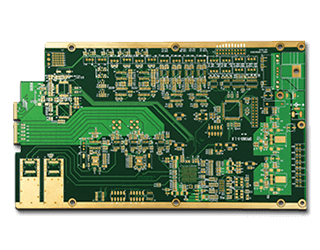

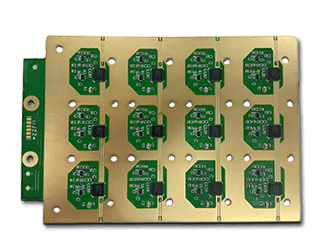

HDI PCB

High Density Interconnect PCB, is a circuit board with relatively high line distribution density using micro-blind and buried via technology.

With the development of high-density, high-precision electronic products, the requirements for circuit boards are also the same. The most effective way to increase PCB density is to reduce the number of vias and precisely set blind and buried vias to meet this requirement, resulting in HDI boards.

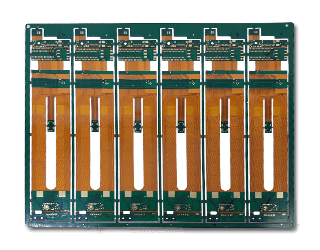

The electrical interconnection between the board layers of HDI is realized through conductive through holes, buried holes and blind holes. Its structure is different from ordinary multi-layer circuit boards. A large number of micro-buried blind holes are used in HDI boards. HDI uses laser direct drilling, while standard PCBs are usually mechanically drilled, so the number of layers and aspect ratios tend to be reduced.

HDI can not only enable more miniaturization of end product designs, but also meet higher standards of electronic performance and efficiency at the same time.

At present, the core pain point and difficulty of HDI manufacturing is the buried hole plug hole. If the HDI buried hole plugging is not done well, there will be major quality problems, including uneven board edges, uneven dielectric thickness, and potholes on the pads. POE is very professional in this area, we have many years of experience to meet different needs, specially customize HDI PCB of different difficulty for you.