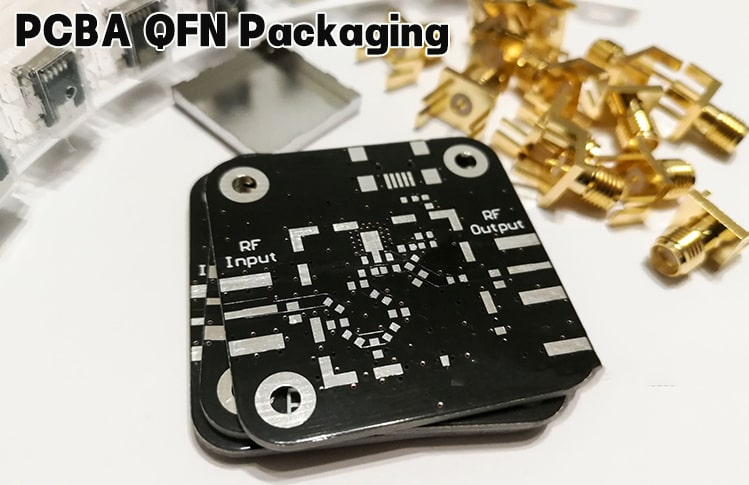

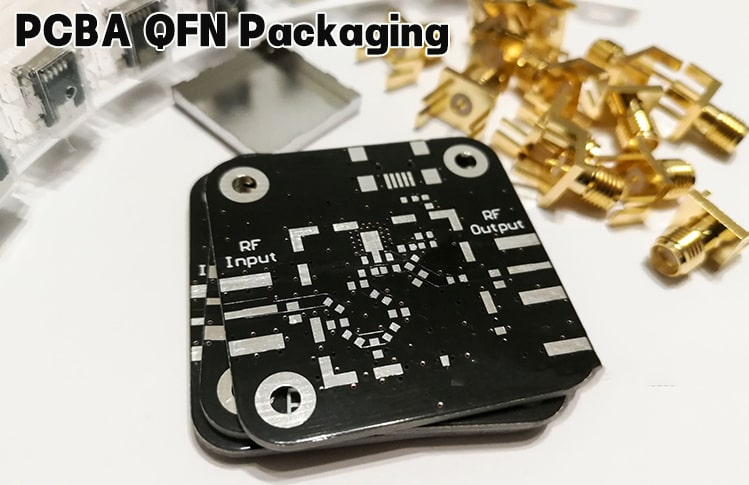

QFN Packaging in PCBA: Thermal Performance and Assembly Control

Quad Flat No-lead (QFN) packaging has become increasingly popular due to its compact size, excellent electrical performance, and superior thermal dissipation. However, these benefits come with strict assembly requirements.

How QFN packaging works and what PCBA manufacturers must control to ensure consistent quality.

Why QFN Is Widely Used

QFN packages feature:

No external leads

Exposed thermal pad on the bottom

Very short electrical connections

These characteristics result in:

Low parasitic inductance

Strong high-frequency performance

Efficient heat transfer into the PCB

Hidden Assembly Challenges of QFN

1. Bottom-Side Solder Joints

Since all solder joints are underneath the component:

Visual inspection is not possible

Solder joint quality must be verified by X-ray

This makes QFN assembly more complex than SOP or QFP packages.

2. Thermal Pad Soldering

The center thermal pad is critical for:

Heat dissipation

Mechanical stability

Improper solder paste volume can cause:

Excessive voiding

Component floating or tilting

Best practice is to use segmented stencil openings to balance solder volume and gas release.

3. Voiding Control

Excessive voids reduce thermal performance and reliability.

In most applications, voiding should be controlled below 25% of the thermal pad area.

PCBA Process Controls for QFN

Optimized stencil design for center pads

Controlled reflow profiles

X-ray inspection for void analysis

Stable PCB flatness and solder mask definition

QFN packaging rewards good process control—but exposes weaknesses very quickly.

Where QFN Packaging Performs Best

Power management ICs

RF and wireless modules

Industrial and automotive electronics