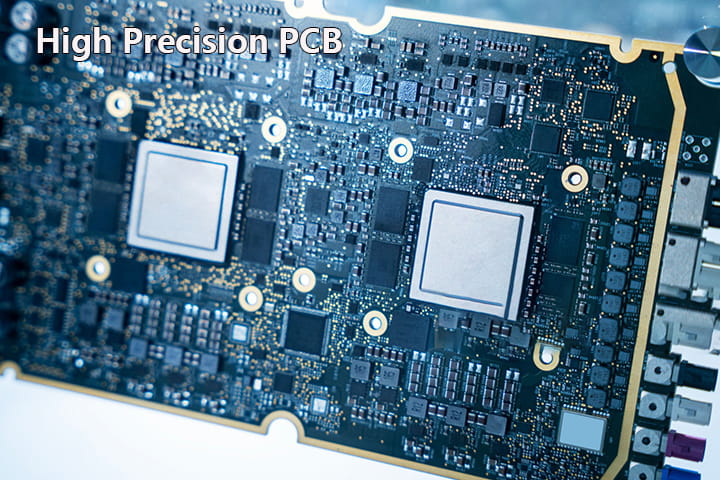

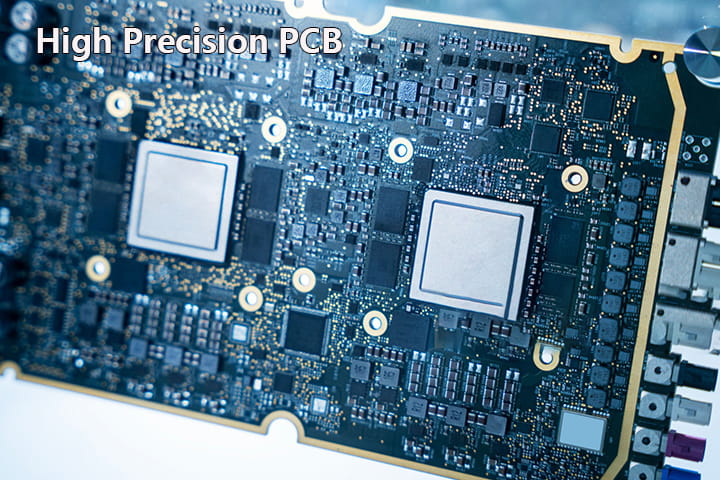

8-Layer vs 12-Layer vs 20-Layer High Precision PCB: What Really Changes in Manufacturing?

In high-performance applications such as servers, telecom infrastructure, industrial automation, and medical systems, PCB layer count directly impacts signal integrity, reliability, and system stability.

Many engineers and sourcing managers ask:

What are the real manufacturing differences between 8-layer, 12-layer, and 20-layer high precision PCBs?

The answer is simple:As layer count increases, manufacturing complexity rises exponentially — not linearly.

It is not just about adding more copper layers.

It is about lamination strategy, alignment accuracy, via structure, impedance control, and long-term reliability.

Let’s break down the real differences.

1. 8-Layer PCB: Mature but Already Precision Manufacturing

Typical Applications

Industrial control boards

Power management modules

Communication sub-boards

Mid-to-high-end electronic systems

Manufacturing Characteristics

Single lamination cycle

Mechanical drilling

Aspect ratio typically ≤ 8:1

Controlled impedance structures

At this stage, precision is already critical when designs include:

4/4 mil trace/space or below

Multiple impedance groups

Dense BGA layouts

Even for 8-layer boards, stable inner-layer registration and lamination profile control are essential.

For manufacturers without solid multilayer experience, risks may include:

Layer misalignment

Impedance deviation

Drill breakout

2. 12-Layer PCB: The Gateway to High-End Multilayer Manufacturing

When moving to 12 layers, manufacturing difficulty increases significantly.

2.1 More Complex Lamination Structures

Possible double lamination cycles

Buried via sub-structures

Increased cumulative alignment tolerance

Each additional lamination introduces:

Thermal expansion control challenges

Thickness tolerance variation

Registration stacking error risks

2.2 Higher Drilling and Plating Requirements

Increased aspect ratio

Higher copper thickness uniformity requirements

Greater via reliability expectations

Poor plating control may lead to:

Barrel cracking

Long-term thermal fatigue failure

2.3 Tighter Reliability Standards

12-layer boards used in high-reliability sectors often must comply with:

IPC-6012 qualification requirements and IPC-A-610 workmanship standards

This is no longer only a production issue — it becomes a system-level reliability concern.

3. 20-Layer PCB: Sequential Lamination + HDI + High-Speed Material Expertise

When layer count reaches 20 or above, manufacturing enters the high-end domain.

Typical Applications

Server motherboards

AI computing modules

High-speed networking equipment

Medical imaging systems

3.1 Sequential Lamination

20-layer boards typically require:

3–4 lamination cycles

Buried via sub-core fabrication

Laser-drilled microvias

Via filling and planarization

Each lamination cycle introduces:

Accumulated thermal stress

Increased registration complexity

Reduced overall yield

This requires advanced lamination equipment and highly controlled process windows.

3.2 Laser Microvias and Via Filling

Common structures include:

HDI stacked microvias

Resin plugging

Copper-filled microvias

Improper control may result in:

BGA voiding

Reliability failure

Delamination during thermal cycling

3.3 High-Speed / Low-Loss Materials

High-layer server boards often use advanced materials such as:

Rogers Corporation high-frequency laminates

Panasonic Megtron series materials

These materials demand:

Precise lamination temperature profiles

Specialized drilling parameters

Accurate impedance verification

Without high-speed material processing experience, impedance stability and layer reliability cannot be guaranteed.

4. Capability Comparison: 8L vs 12L vs 20L

| Parameter | 8-Layer

| 12-Layer

| 20-Layer

|

Lamination Cycles

| 1 | 1-2 | 2-3 |

Sequential Lamination

| No

| Possible

| Required

|

HDI Structure

| Rare

| Partial

| Common

|

Laser Microvias

| Limited

| Moderate

| Extensive

|

High-Speed Materials

| Rare

| Sometimes

| Common

|

Yield Stability

| High

| Medium

| Lower

|

Manufacturing Barrier

| Medium

| High

| Very High

|

5. Why High-Layer PCBs Require an Experienced Manufacturer

As layer count increases:

- Any process defect can scrap the entire panel

- Rework is almost impossible

- Material cost becomes significant

- Yield management becomes critical

A qualified high-layer PCB manufacturer should offer:

✔ Sequential lamination capability

✔ HDI microvia fabrication

✔ Laser drilling equipment

✔ TDR impedance testing

✔ Cross-section micro analysis

✔ IPC Class 3 manufacturing standard

6. From PCB to PCBA: Why One-Stop Capability Matters

For high-end applications such as servers or industrial systems, PCB fabrication alone is not enough.

Customers increasingly require:

High-layer PCB fabrication

BGA assembly

X-ray inspection

IC programming

Functional testing

A one-stop PCB + SMT solution reduces:

Lead time

Supply chain risk

Communication cost

Overall project uncertainty

Final Thoughts

8-layer boards represent solid multilayer capability.

12-layer boards mark entry into high-end manufacturing.

20-layer boards reflect full process-system strength.

If your project involves:

High-speed signal design

Server or AI systems

Industrial control platforms

Medical-grade electronics

Early DFM communication with an experienced engineering team is critical.

Proper stack-up planning, aspect ratio control, and lamination strategy can significantly improve yield and long-term reliability.