BGA Packaging in PCBA Manufacturing: Challenges, Processes, and Best Practices

Ball Grid Array (BGA) packaging is widely used in high-speed, high-density electronic designs. From communication equipment to automotive and computing applications, BGA enables large pin counts within a compact footprint. However, BGA is also one of the most demanding packages in PCBA manufacturing.

This article explains why BGA packaging is challenging, how it impacts PCB assembly, and what best practices are required to achieve reliable results.

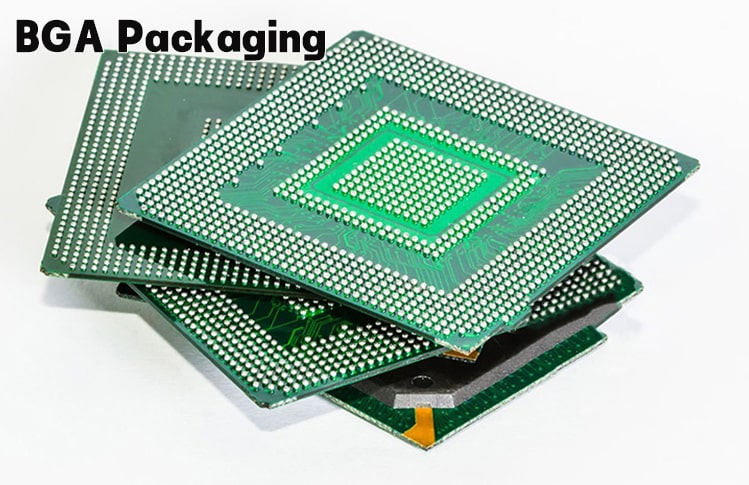

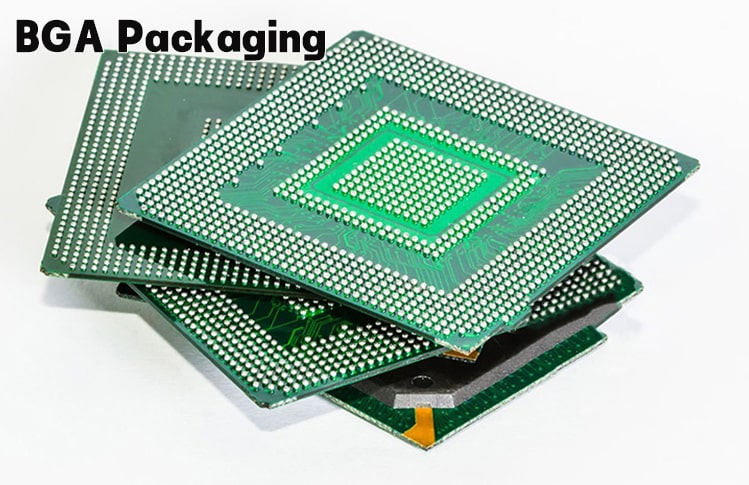

What Is BGA Packaging?

BGA components use an array of solder balls located underneath the package instead of traditional leads. During reflow soldering, these balls melt and form solder joints directly with PCB pads.

Compared to leaded packages, BGA offers:

Higher I/O density

Shorter electrical paths

Better signal integrity for high-speed designs

Key Manufacturing Challenges of BGA Assembly

1. Invisible Solder Joints

All BGA solder joints are hidden under the component after assembly. This means:

Visual inspection is impossible

Defects such as voids, bridges, or open joints cannot be detected by AOI alone

X-ray inspection is mandatory for reliable BGA assembly.

2. PCB Design Dependency

BGA performance is closely tied to PCB design quality:

HDI structures (microvias, blind/buried vias) are often required

Pad design (NSMD vs SMD) affects solder joint reliability

Via-in-pad designs require proper filling and planarization

Poor PCB design can significantly reduce BGA yield, even with perfect assembly processes.

3. Reflow Profile Sensitivity

BGA solder balls are highly sensitive to:

Temperature ramp rate

Peak temperature

Time above liquidus

Uneven heating may result in head-in-pillow defects or incomplete solder wetting.

Best Practices for Reliable BGA PCBA

Perform DFM review before prototyping

Use X-ray inspection for all BGA assemblies

Control moisture sensitivity levels (MSL)

Validate reflow profiles during trial builds

Apply first article inspection (FAI) for new designs

Typical Applications of BGA Packaging

Networking and communication systems

Automotive electronics (ADAS, control units)

AI, computing, and embedded processing modules

BGA packaging is not just a component choice—it is a system-level manufacturing decision that requires experienced PCBA capabilities.