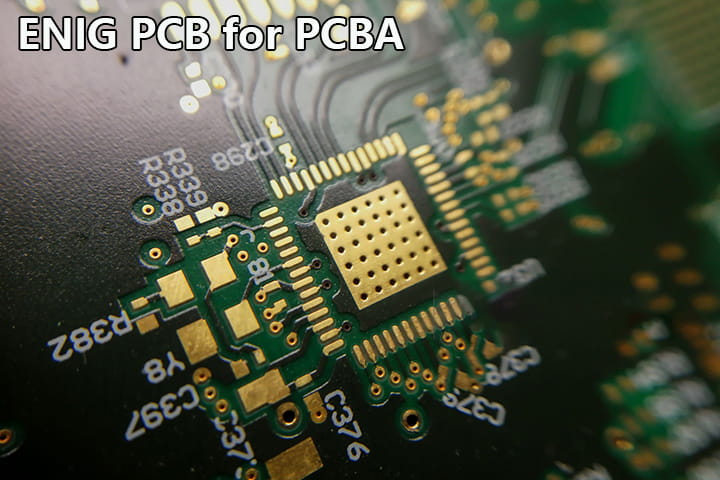

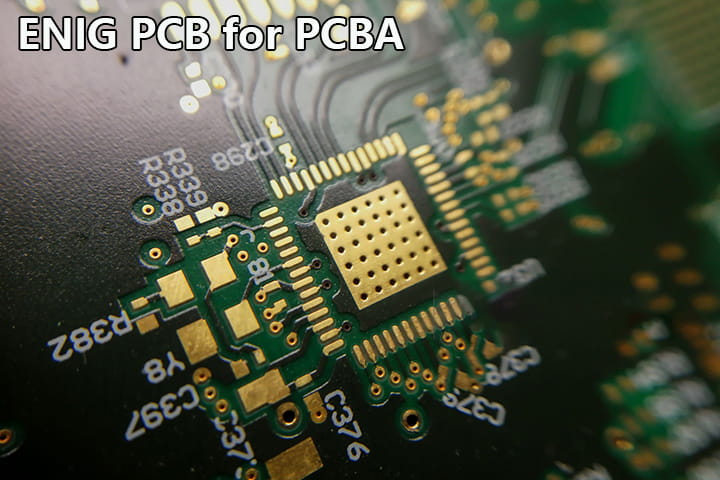

ENIG Surface Finish in PCBA: When Is ENIG the Best Choice?

In PCBA manufacturing, ENIG (Electroless Nickel Immersion Gold) is often regarded as a “premium” surface finish.

However, ENIG is not simply chosen because it is more expensive—it is chosen because it solves specific manufacturing and reliability problems.

What Is ENIG Surface Finish?

ENIG is a two-layer surface finish consisting of:

An electroless nickel layer deposited on copper

A thin immersion gold layer protecting the nickel from oxidation

This structure provides excellent surface flatness and stable solderability, making ENIG widely used in high-density and high-reliability PCBA projects.

Why ENIG Is Preferred in High-End PCBA

1. Excellent Flatness for Fine-Pitch Assembly

From a PCBA standpoint, surface flatness directly affects solder joint consistency.

ENIG performs especially well with:BGA packages,QFN / LGA,0201 and smaller components

Flat pads reduce solder bridging and head-in-pillow defects during reflow.

2. Wide SMT Process Window

ENIG offers:Stable wetting behavior,Strong tolerance to reflow profile variation,Good performance in multi-pass reflow processes

This makes ENIG suitable for complex assemblies and multi-stage PCBA processes.

3. Long Shelf Life and Storage Stability

Compared with OSP and immersion silver, ENIG provides:

Better oxidation resistance

Longer storage time before assembly

This is particularly important for projects with:Long logistics cycles

Staggered production schedules

Cost Consideration: Is ENIG Always Expensive?

ENIG typically has a higher unit PCB cost, but in mass production:Higher yield,Lower rework rate,More stable assembly,often offset the initial cost difference.

👉 In many high-end PCBA projects, ENIG reduces total manufacturing cost, not increases it.

Typical Applications for ENIG PCBs- Industrial control systems

- Automotive electronics

- Medical devices

- Communication equipment with high-density BGAs

When ENIG May Not Be NecessaryENIG may be over-specified for:

Low-density consumer electronicsSingle-pass, cost-driven projects

👉 In such cases, OSP or immersion silver may be more appropriate.

Related reading:

OSP Surface Finish in PCBA: Cost vs Reliability

Immersion Silver Surface Finish for PCBA Applications

ENIG is best suited for PCBA projects that prioritize:Assembly yield

Long-term reliability

Manufacturing stability

It is a strategic choice, not just a premium option.