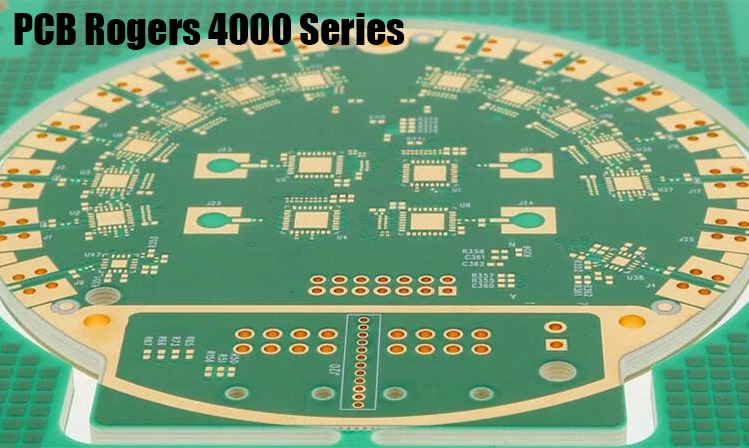

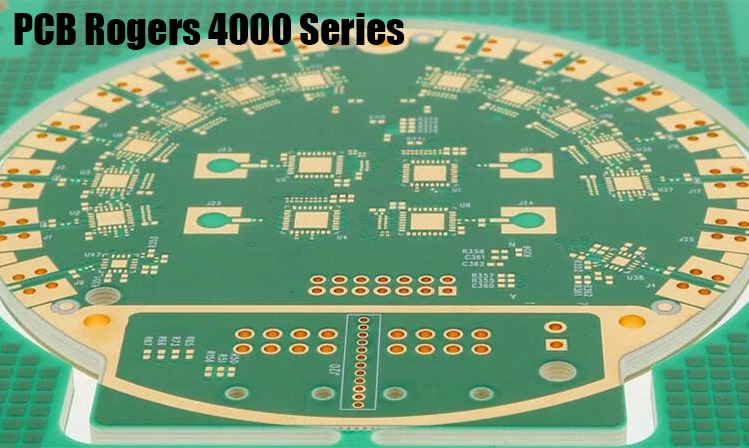

Rogers 4000 Series PCB Materials and Their Advantages

When it comes to high-frequency and high-speed PCB applications, the choice of base material makes all the difference. The Rogers 4000 series has become one of the most trusted options for engineers and designers worldwide — offering excellent electrical performance, mechanical stability, and processing reliability.

What Is Rogers 4000 Series?

The Rogers 4000 series is a family of hydrocarbon-ceramic laminate materials designed for high-frequency PCB applications. Unlike traditional FR-4, these materials are engineered to deliver superior dielectric properties, ensuring stable performance across wide frequency and temperature ranges.

Common materials in this series include:

RO4003C

RO4350B

RO4360G2

RO4835

Each variant provides specific dielectric constants (Dk) and loss factors (Df), allowing designers to choose the right balance of signal integrity, mechanical strength, and cost.

Key Advantages of Rogers 4000 Series

Excellent Electrical Performance

Rogers 4000 materials have low dielectric loss (Df) and consistent dielectric constant (Dk), making them ideal for high-speed digital and RF applications. They maintain signal integrity even at GHz-level frequencies — crucial for 5G, radar, and communication systems.

Superior Thermal Stability

With a low coefficient of thermal expansion (CTE), Rogers laminates minimize dimensional changes during soldering and thermal cycling. This ensures reliable multilayer alignment and long-term durability.

Compatibility with FR-4 Processing

One of the biggest advantages is that Rogers 4000 series laminates can be processed using standard FR-4 fabrication techniques. This reduces cost and complexity while maintaining high performance — an ideal balance for engineers and manufacturers.

High Reliability in Harsh Environments

Thanks to their ceramic-filled hydrocarbon composition, these materials offer excellent moisture resistance, chemical stability, and mechanical strength. They perform consistently in outdoor, automotive, and aerospace environments.

Wide Range of Applications

Rogers 4000 materials are widely used in:

5G base stations

Antenna and radar systems

Automotive ADAS radar

Satellite and communication modules

High-speed digital circuits

Why Choose Rogers 4000 for Your PCB Project

For designers seeking high performance without the cost of PTFE-based materials, the Rogers 4000 series is the perfect solution. It bridges the gap between standard FR-4 and expensive microwave laminates, providing a cost-effective path to high-frequency reliability.

At PCBAmake, we have extensive experience in manufacturing and assembling PCBs using Rogers materials, including multilayer RF and microwave designs. Whether you’re developing a communication device, radar system, or high-speed module, our engineering team can help you choose the most suitable Rogers laminate and ensure a precise, high-quality production process.

Ready to upgrade your PCB performance?

Contact PCBAmake to learn more about our Rogers PCB manufacturing capabilities and one-stop PCBA solutions.