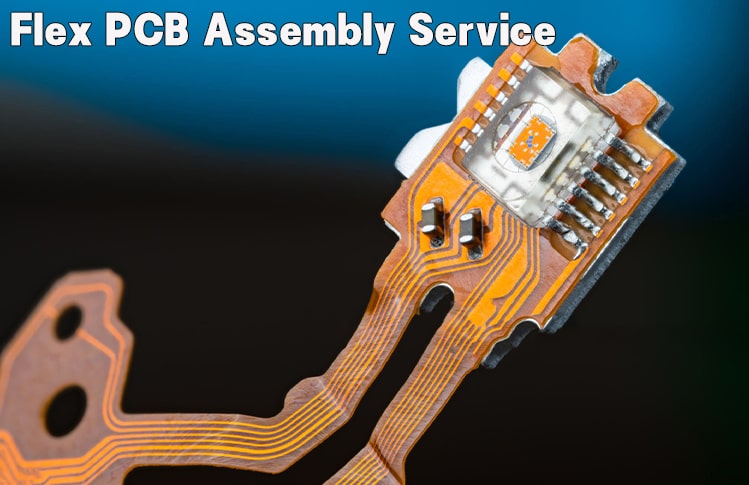

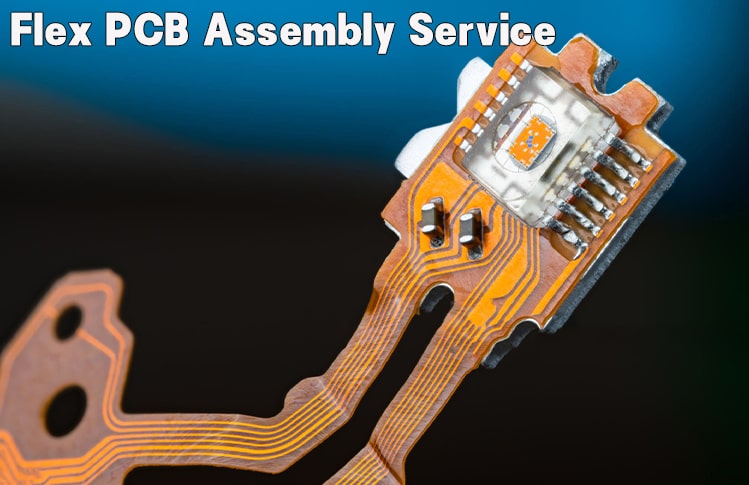

Flex PCB Assembly Service: Engineering Precision for Reliable Flexible Electronics

As electronic products continue to become thinner, lighter, and more compact, flex PCB assembly has become a critical manufacturing capability across industries such as consumer electronics, medical devices, automotive systems, and industrial control. Compared with rigid PCBs, flexible printed circuit boards offer unique mechanical advantages—but they also introduce higher requirements for assembly expertise, process control, and material handling.

This article explains what a professional flex PCB assembly service involves, the key technical challenges, and how experienced manufacturers ensure stable quality from prototype to volume production.

What Is Flex PCB Assembly?

Flex PCB assembly refers to the process of mounting electronic components onto flexible printed circuit boards (FPCs) using SMT, selective soldering, or hybrid assembly methods. Unlike rigid boards, flex circuits can bend, fold, or twist during operation, which places additional demands on solder joint reliability and material compatibility.

Typical flex PCB assemblies include:

Single-layer and double-layer FPCs

Multilayer flex circuits

Rigid-flex PCB assemblies

High-density fine-pitch component layouts

A reliable flex PCB assembly service must account for both electrical performance and mechanical durability throughout the product lifecycle.

Key Challenges in Flex PCB Assembly

Flex PCB assembly is significantly more complex than standard rigid PCB assembly. Some of the most common technical challenges include:

1. Board Handling and Stability

Flexible circuits lack inherent rigidity, making them difficult to transport through SMT lines. Professional assembly typically requires custom carriers, stiffeners, or temporary fixtures to ensure accurate placement and reflow stability.

2. Thermal Sensitivity

FPC materials are more sensitive to heat than FR-4. Reflow profiles must be carefully optimized to prevent:

Material shrinkage

Warpage

Adhesive degradation

Copper trace deformation

Advanced flex PCB assembly services use controlled reflow profiles and nitrogen reflow when necessary to protect sensitive substrates.

3. Fine-Pitch and High-Density Assembly

Flex PCBs are often used in space-constrained designs, requiring:

Fine-pitch BGAs, QFNs, or chip-scale packages

High-precision solder paste printing

Accurate placement and AOI/X-ray inspection

This demands high-end SMT equipment and experienced process engineers.

Flex PCB Assembly Process Overview

A standard professional flex PCB assembly service typically includes the following steps:

DFM & DFA Review

Design for Manufacturability and Assembly analysis ensures pad design, stiffener placement, and panelization are optimized for flex assembly.

Material Preparation

FPC boards are prepared with required stiffeners or carriers to ensure flatness during SMT processing.

Solder Paste Printing

Controlled stencil design and paste volume are critical to avoid insufficient or excessive solder on flexible substrates.

SMT Placement

High-accuracy pick-and-place machines ensure reliable mounting of fine-pitch components.

Reflow Soldering

Customized temperature profiles minimize thermal stress on flex materials.

Inspection & Testing

AOI, X-ray inspection, and electrical testing verify solder joint integrity and circuit performance.

Why Choose a Professional Flex PCB Assembly Service?

Choosing the right flex PCB assembly partner directly impacts product reliability and time-to-market. A professional manufacturer offers:

Proven experience with flex and rigid-flex PCB assembly

Dedicated fixtures and carriers for flexible boards

Strict process control aligned with IPC standards

Component sourcing traceability and anti-counterfeit measures

Scalability from prototype to mass production

For applications where mechanical movement, vibration, or repeated bending is involved, assembly quality is as important as PCB design itself.

Applications of Flex PCB Assembly

Flex PCB assembly services are widely used in:

Wearable and portable electronics

Medical diagnostic and monitoring devices

Automotive cameras, sensors, and control modules

Industrial automation and robotics

Aerospace and high-reliability electronics

Each application places unique demands on assembly reliability, cleanliness, and long-term performance.

Final Thoughts

Flex PCB assembly is not simply “rigid PCB assembly on a flexible board.” It requires specialized knowledge, equipment, and quality control systems. Partnering with an experienced flex PCB assembly service provider helps ensure stable performance, reduced failure rates, and smoother transitions from prototyping to production.

As flexible electronics continue to evolve, manufacturers with deep flex PCB assembly expertise will play a key role in supporting next-generation product designs.