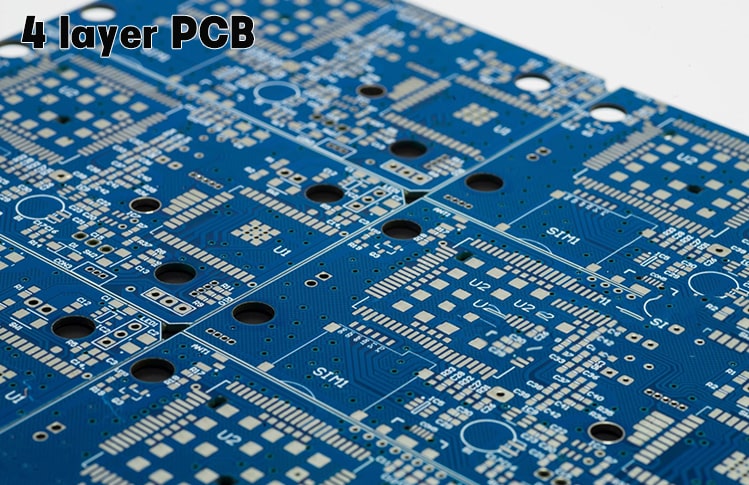

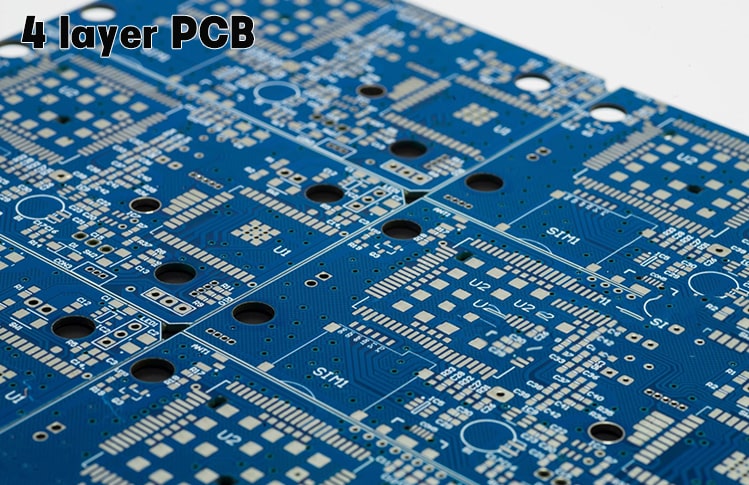

4 Layer PCB: Structure, Advantages, Applications, and Manufacturing Insights

Compared with traditional 2 layer PCBs, a 4 layer PCB offers better signal integrity, improved EMI control, and higher routing density—making it a reliable choice for industrial, automotive, medical, and consumer electronics.

At PCBAMake, we manufacture and assemble high-quality 4 layer PCBs with stable processes, strict IPC standards, and one-stop PCBA services.

What Is a 4 Layer PCB?

A 4 layer PCB is a multilayer printed circuit board consisting of four copper layers laminated together with insulating material (prepreg and core). A typical stack-up includes:

Top Layer – Component placement and high-speed signal routing

Inner Layer 1 – Ground plane (GND)

Inner Layer 2 – Power plane (PWR) or signal plane

Bottom Layer – Additional signal routing and components

This structure allows designers to separate signal, power, and ground layers, significantly improving electrical performance and layout efficiency.

Why Choose a 4 Layer PCB?

Compared with 2 layer boards, 4 layer PCBs provide several key advantages:

1. Better Signal Integrity

Dedicated ground and power planes reduce impedance and signal noise, making 4 layer PCBs suitable for high-speed and high-frequency circuits.

2. Improved EMI / EMC Performance

The internal ground plane acts as a shield, helping to suppress electromagnetic interference and improve EMC compliance.

3. Higher Routing Density

With two internal layers, designers can route more traces without increasing board size—ideal for compact electronic devices.

4. More Stable Power Distribution

A solid power plane ensures consistent voltage levels and reduces power-related noise across the PCB.

Common 4 Layer PCB Stack-Up Options

At PCBAMake, we support flexible stack-up configurations based on customer requirements:

Signal / GND / PWR / Signal (most common)

Signal / GND / Signal / GND (for higher EMI control)

Signal / PWR / GND / Signal (special design needs)

Each stack-up is reviewed by our engineers to ensure manufacturability and performance.

Applications of 4 Layer PCBs

Because of their balance between performance and cost, 4 layer PCBs are widely used in:

Industrial control systems

Automotive electronics and control modules

Medical devices

Communication equipment

Embedded systems and IoT devices

Consumer electronics with higher integration requirements

Key Manufacturing Considerations for 4 Layer PCB

Producing a reliable 4 layer PCB requires precise control at every stage:

Material Selection

FR-4 is the most commonly used material, but high-Tg or low-loss materials may be required for specific applications.

Layer Alignment & Lamination

Accurate layer registration during lamination is critical to ensure stable electrical performance.

Controlled Impedance

For high-speed designs, impedance control is essential and must be managed during stack-up design and production.

Quality Inspection

AOI, electrical testing, and cross-section analysis are used to verify inner-layer quality and overall PCB reliability.

At pcbamake, all 4 layer PCBs are manufactured under strict IPC standards, ensuring consistent quality from prototype to mass production.

One-Stop 4 Layer PCB & Assembly Service at PCBAMake

As a professional PCB & PCBA manufacturer, pcbamake provides one-stop 4 layer PCB solutions, including:

- 4 layer PCB fabrication

- SMT & THT assembly

- Component sourcing (original or customer-specified alternatives)

- IC programming and functional testing

- Conformal coating and final inspection

Whether you need quick-turn prototypes or volume production, our engineering team supports your project from design review to final delivery.

A 4 layer PCB is an excellent choice for designs that require better signal performance, higher reliability, and compact layouts. Choosing an experienced manufacturer is key to achieving stable quality and long-term product success.

If you are looking for a reliable 4 layer PCB manufacturer and assembly partner, pcbamake is ready to support your project with professional engineering, advanced equipment, and global EMS experience.