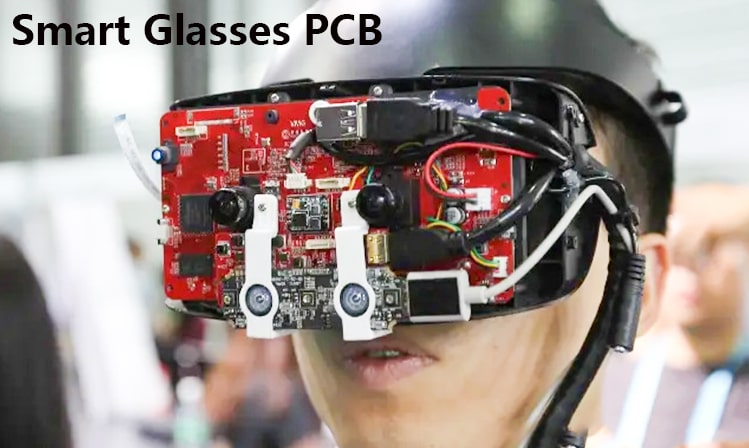

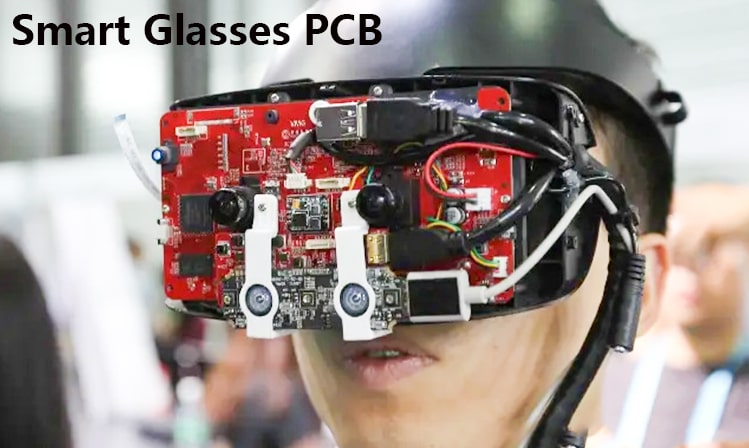

PCB in smart glasses

Benefiting from the deep integration of AI big models and augmented reality technology, the smart glasses market has been heating up recently, and online and offline sales are hot.

According to the head of the digital business department of an e-commerce platform, the smart glasses market has shown explosive growth, with transaction volume increasing by more than 8 times year-on-year. Data shows that global smart glasses shipments are expected to reach 12.8 million units in 2025, a year-on-year increase of 26%; among them, the Chinese market will exceed 2.75 million units, a year-on-year increase of 107%, ranking first in the world.

There is a close relationship between smart glasses and PCB. PCB is the core component of smart glasses, and its design and manufacturing quality directly affect the performance and user experience of smart glasses.

The role of PCB in smart glasses

Integrated core processor: The mainboard of smart glasses will integrate core processing devices such as CPU and memory. These components are usually assembled together through PCBA (Printed Circuit Board Assembly) technology to achieve efficient data processing and intelligent functions.

Sensors and communication modules: Smart glasses need to collect environmental information through sensors and exchange data with external devices (such as smartphones) through communication modules. These sensors and communication modules are also integrated onto the motherboard through PCBA technology.

Power management: To ensure the long-term use of smart glasses, power management and battery interface are implemented through PCBA technology to optimize energy consumption and provide a stable power supply.

Display and audio output: Some smart glasses have display functions, and display driver and audio output modules need to be integrated through PCBA technology to provide user interface and interactive experience.

Camera and optical module: The camera and optical module of smart glasses need to be connected to the motherboard through PCBA technology to achieve functions such as image capture and augmented reality.

Specific application and technical requirements of PCB in smart glasses design

Appearance and size design: The appearance design of PCB needs to fit the contour of smart glasses to avoid sharp corners causing friction or discomfort to the skin. In addition, using thinner substrates and optimizing component layout can reduce the overall thickness and volume of the device and improve wearing comfort.

Weight distribution and balance: The weight of PCB and the components mounted on it needs to be evenly distributed to avoid local overweight causing discomfort. By carefully planning the layout of PCB and components such as batteries and displays, the weight of the device is evenly distributed when worn, without causing local pressure on the wrist or head. High-density interconnect technology : High-end PCB technologies such as high-density interconnect (HDI) boards and rigid-flex boards are widely used in smart glasses. These technologies can meet the requirements of smart glasses for high precision and complex wiring, and improve the performance and reliability of the device. PCB manufacturing and the development of smart glasses are inseparable. If you have any needs in this regard, please feel free to contact us. PCBAMake will help you take the field of smart glasses in wearable technology to the next level.