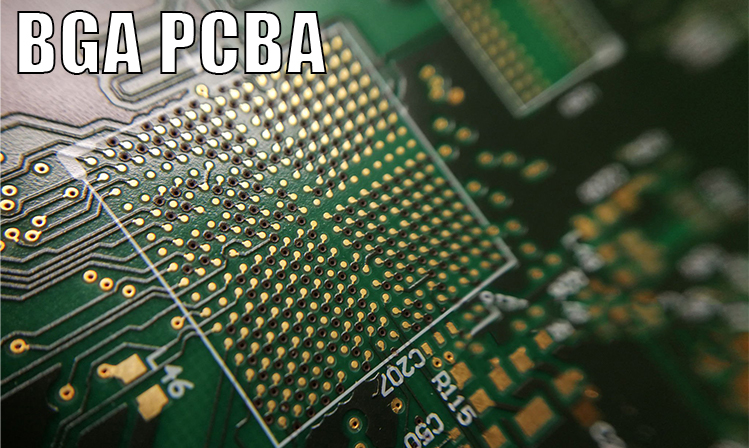

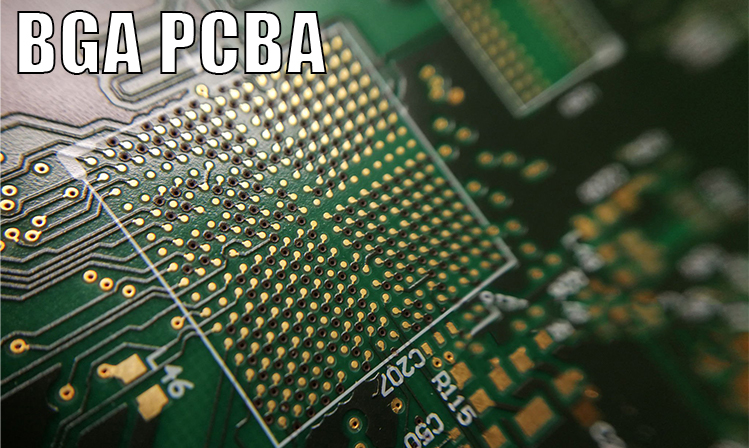

What Makes BGA PCBA Essential in Modern Electronics?

In today’s electronics industry, BGA PCBA (Ball Grid Array Printed Circuit Board Assembly) is one of the most important technologies. From consumer devices to automotive and industrial systems, BGA packages allow designers to achieve higher performance in smaller, more reliable products.

What is BGA in PCBA?

BGA stands for Ball Grid Array. Unlike traditional packages with pins, BGA uses small solder balls arranged in a grid under the chip. During assembly, these solder balls are melted to connect the component securely to the PCB.

The main benefits include:

Compact size – More I/O connections in less space.

Stable performance – Shorter paths mean lower signal loss and less interference.

Better heat management – The grid structure helps spread heat effectively.

Why BGA PCBA Matters for Global Customers

For companies in Europe and North America, product reliability and long-term performance are critical. BGA technology helps achieve this by:

Supporting high-speed processors, memory, and communication chips.

Reducing failure risks with strong solder joints.

Enabling compact designs without sacrificing performance.

Challenges in BGA Assembly

BGA assembly is more complex compared to other packages:

Soldering accuracy – Requires precise temperature control during reflow.

Inspection – Joints are hidden under the package, so X-ray inspection is necessary.

Rework – Repairing BGA components takes advanced equipment and skilled technicians.

Our Capabilities in BGA PCBA

We provide complete PCB manufacturing and assembly services, including:

High-quality multilayer PCBs designed for BGA layouts.

Professional BGA soldering, reballing, and rework capabilities.

Advanced testing: X-ray, AOI, and functional tests.

Turnkey service covering PCB fabrication, component sourcing, and full assembly.

With years of experience serving clients in Europe and the U.S., we know the quality standards expected and deliver reliable solutions tailored to your needs.

FAQ About BGA PCBA

Q1: What is the main advantage of BGA over QFP?

BGA offers more connections in a smaller footprint, better electrical performance, and improved heat dissipation.

Q2: How is BGA quality checked?

Since solder joints are hidden, X-ray inspection is the standard method to verify connection quality.

Q3: Can BGA components be repaired?

Yes, but it requires specialized equipment and trained technicians to remove, reball, and reattach the package.

Q4: What industries commonly use BGA PCBA?

BGA PCBA is widely used in telecom, automotive, consumer electronics, industrial automation, and medical devices.

👉 Whether you need prototype assembly or mass production, we can support your projects with reliable BGA PCBA solutions.