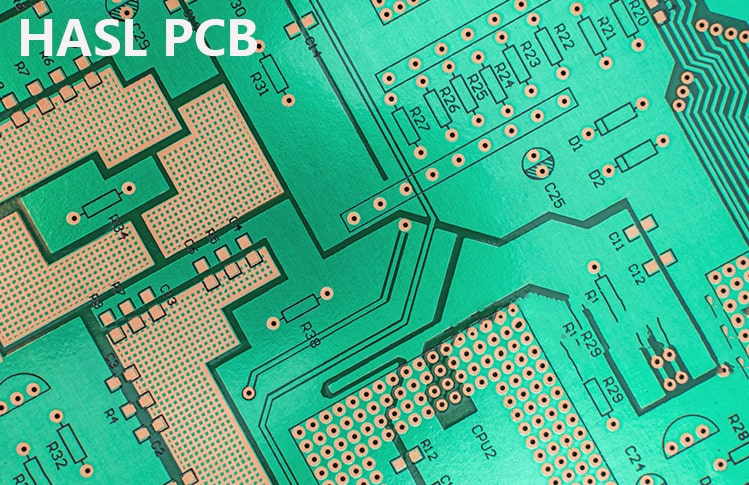

What Is HASL in PCB Manufacturing? A Simple Guide for Electronics Buyers

When choosing a surface finish for your PCB, one of the most common options you will see is HASL, short for Hot Air Solder Leveling. It has been used in the PCB industry for many years because it is affordable, reliable, and suitable for many types of electronic products.

This article gives you a simple and clear overview of the HASL process, its advantages, its limitations, and when it is the right choice for your project.

1. What Is HASL?

HASL (Hot Air Solder Leveling) is a surface finish applied to the exposed copper pads of a PCB.

It works by coating the pads with molten solder and then blowing off the excess solder using hot air knives.

The purpose:

To protect the copper from oxidation and to provide a solderable surface for component assembly.

Two types of HASL:

Lead-free HASL (RoHS compliant)

Lead HASL (traditional, not allowed in RoHS products)

Most global customers today choose lead-free HASL.

2. How the HASL Process Works

The process includes several simple steps:

The PCB is dipped into a bath of molten solder.

The solder coats all exposed copper pads.

Hot air knives blow off the excess solder.

The surface cools and forms a protective solder layer.

The result is a shiny, solderable finish that is very durable.

3. Advantages of HASL

HASL remains one of the most widely used finishes because it offers several clear benefits:

✔ Very cost-effective

It is one of the lowest-cost PCB surface finishes available.

✔ Good solderability

The soldered pads wet well during assembly, making it easy to solder components.

✔ Strong and durable finish

The solder coating protects the copper and handles storage well.

✔ Ideal for through-hole and larger SMD components

Perfect for many standard consumer and industrial applications.

4. Limitations of HASL

While HASL is popular, it is not perfect for every design.

✘ Not ideal for very small pads or fine-pitch components

Because the surface can be slightly uneven, it may not work well for 0.5 mm pitch BGA or smaller.

✘ Higher thermal stress

The PCB is exposed to high temperature during the solder dip, which may affect sensitive materials.

✘ Not as flat as other finishes

If your design requires a very flat surface (e.g., HDI or micro-BGA), you may prefer ENIG or ENEPIG.

5. When Should You Choose HASL?

HASL is a good fit for projects where:

Cost is a key factor

The design does not require very fine-pitch components

You want strong solderability and durability

You are producing consumer electronics, industrial boards, or general-purpose PCBs

For high-frequency or high-density designs, another finish (such as ENIG) may be better.

6. HASL vs. Lead-Free HASL

Most international customers choose lead-free HASL, because:

It meets RoHS regulations

It is safer for consumer electronics

It has similar performance to traditional HASL

Our factory provides both options based on customer requirements.

HASL is a simple, reliable, and cost-effective PCB surface finish that works well for many applications. It offers great solderability and durability, making it one of the most commonly selected finishes worldwide. However, for fine-pitch or high-density designs, other surface finishes may offer better flatness and performance.

At PCBAMake, we provide a full range of PCB surface finishes, including

HASL, Lead-Free HASL, ENIG, ENEPIG, OSP, Immersion Tin, and more.

We can help you choose the right finish based on your design, application, and budget.