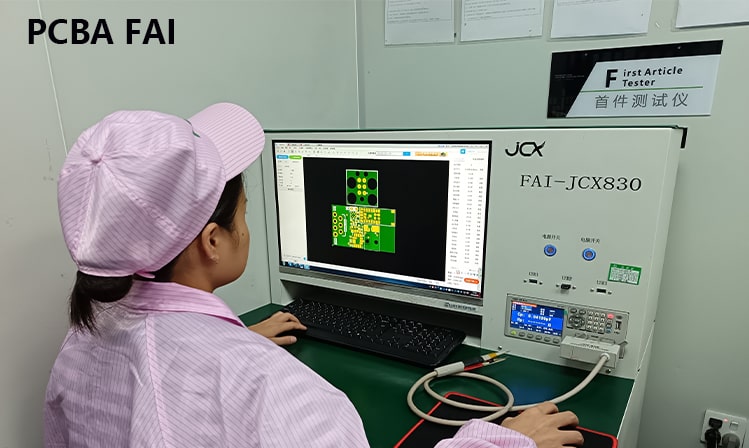

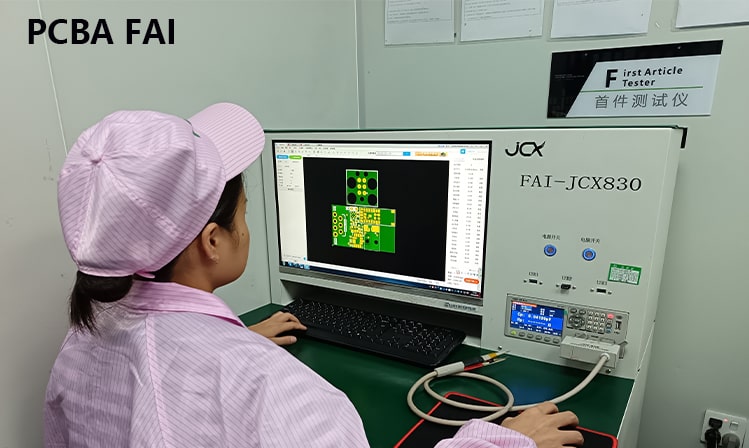

First-article inspection: the quality guardian in PCBA processing

What is first-article inspection?

First-article inspection is a key step before PCBA mass production, that is, to conduct a comprehensive inspection of the first batch of assembled sample boards to ensure that they meet the design requirements and process standards. Only after the first-article inspection is qualified will it enter mass production. Its core function is to find problems in the early stage of production and prevent defective products from flowing into the subsequent process.

First-article inspection mainly focuses on:

✔ Component accuracy: whether the model, specification, and polarity are consistent with the design

✔ Welding quality: Check for problems such as cold soldering and short circuit to ensure reliable solder joints

✔ Electrical performance: test key indicators such as voltage, current, and signal transmission

✔ Appearance inspection: confirm that there are no scratches, dirt or damage

First-article inspection is not only a technical process, but also a key link in quality assurance. It can detect potential defects in advance, reduce the flow of defective products into the market, and reduce production costs.

The importance of first-article inspection in PCBA processing

1. Improve product quality and reduce defects

First-article inspection is the first line of defense for PCBA quality. Without it, once mass production goes wrong, it may lead to a large number of defective products. Even a component that is misplaced or poorly soldered may cause the entire circuit board to fail.

2. Improve efficiency and reduce rework rate

PCBA rework is not only time-consuming, but also increases costs. First-article inspection ensures stable operation of the production line and reduces production interruptions by discovering problems in advance. For example, we once discovered component offset problems through first-article inspection, and timely adjustments avoided batch rework.

3. Ensure accurate implementation of customer needs

First-article inspection usually includes customer confirmation, and engineers and customers jointly check samples to ensure that the product fully meets the requirements.

4. Save costs and reduce waste

The defective rate directly affects the manufacturing cost. First-article inspection can effectively reduce the defective rate (can be controlled below 1%), reduce material waste and labor loss.

Follow us to learn more about PCBA service processing, proofing, and OEM technology! Welcome to leave a message for consultation!